METHOD FOR CUTTING FLEXIBLE TUBING Flexible tubing has a tendency to spring-back or twist when it is cut. This spring-back or twist action causes the tubing diameter to expand, resulting in an over-sized piece of tubing. Once the tubing has expanded it is very difficult to return to its original dimension

A BERNZ-0-MATIC torch or any other comparative brand can be used for soldering. It is important that the solder flows down between the convolutions. A saw blade with 32 or 24 teeth per inch will be the best for cutting. |

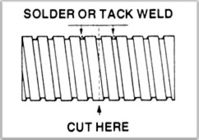

When cutting flexible tubing, to

eliminate spring-back or twisting of the tubing a small tack weld or a drop of solder

should be placed on each side of the cutting point between the convolutions. This should

be done before attempting to make a cut.

When cutting flexible tubing, to

eliminate spring-back or twisting of the tubing a small tack weld or a drop of solder

should be placed on each side of the cutting point between the convolutions. This should

be done before attempting to make a cut.